Arc Flash Hazard Analysis

Arc flash studies to quantify incident energy, define safe working distances, and provide labels, PPE guidance, and documentation that align with NFPA 70E and IEEE 1584.

Arc flashes are low-probability but high-consequence events. A proper study helps you understand where the risk exists, how severe it can be, and what protection and work practices are required so people go home safe after every shift.

What Is An Arc Flash And Why It Matters

An arc flash is a rapid release of energy caused by an electrical fault through air, often accompanied by an arc blast. In a fraction of a second, temperatures can reach tens of thousands of degrees, generating intense radiant heat, molten metal, high sound levels, and pressure waves.

For workers standing in front of a piece of equipment, the questions are:

- How much incident energy will reach the worker at a realistic working distance?

- What level of PPE is required to work safely on or near that equipment?

- Are there settings or equipment changes that can reduce that energy?

Arc flash hazard analysis answers those questions in a systematic, documented way.

When An Arc Flash Study Is Required Or Recommended

Typical triggers for a full or updated analysis:

- New construction or major service upgrades

- Replacement of switchgear, switchboards, MCCs, or large panelboards

- Addition or replacement of transformers, generators, or large motors

- Reconfiguration of feeders and distribution sections

- The last study is older than five years

- Changes to codes or corporate safety standards that require updated labeling and PPE guidance

Our Process

1. Listen and define the scope

We review your goals, existing drawings, and any prior studies, then define which buildings, rooms, and equipment will be modeled and labeled.

2. Collect data and build the model

We gather equipment information from drawings and field visits, then build or update a detailed power system model with fault current, clearing times, and system impedance.

3. Perform arc flash calculations

Using IEEE 1584 methods, we calculate incident energy and arc flash boundaries at each location within the study scope.

4. Evaluate results and recommend improvements

We review high-energy locations, evaluate possible setting changes or equipment options, and discuss trade-offs with your team.

5. Documentation, labels, and review

We prepare the written report, schedules, updated one-lines, and label files, and meet with your team to walk through the results and next steps.

What We Deliver

A typical arc flash hazard analysis from Apex Arc Flash Engineering includes:

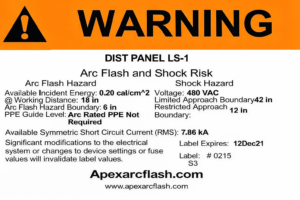

- Arc flash model and calculations based on IEEE 1584 methods

- Incident energy and arc flash boundary at each studied bus or equipment location

- Arc flash labels in a consistent layout, ready for printing and installation

- One-line diagrams that match the model and field conditions

- Summary tables for management and safety teams

- Recommended protective device settings where adjustments can reduce incident energy without compromising coordination

- A clear narrative explaining methods, assumptions, and limitations of the study

What We Need From You

To scope and execute an arc flash hazard analysis efficiently, we typically request:

- Existing one-line diagrams and panel schedules, if available

- Service and transformer information (utility short-circuit data when possible)

- Access for field verification and equipment nameplate photos

- Any previous studies or protective settings documents

- Site safety rules for escorting and PPE during field work

Codes And Standards

Our arc flash work is driven by current industry standards and codes, including:

- NFPA 70E: requirements for arc flash risk assessment, labeling, and PPE selection

- IEEE 1584: methods for calculating arc flash incident energy and boundaries

- NEC / NFPA 70: requirements such as equipment marking and working space

- OSHA expectations for electrical safe work practices and hazard assessment

We align our deliverables with your internal safety programs and any corporate EHS requirements.

FAQs

Q: Do you need to shut down power to perform the study?

Most data collection is done with equipment de-energized or in normal operation following your lockout / tagout procedures. We do not perform energized work unless absolutely necessary and agreed in advance.

Q: How often does the study need to be updated?

An arc flash study must be updated whenever changes occur in the electrical distribution system that could affect the results of the analysis, and it should be reviewed for accuracy at intervals not exceeding five years.

Q: Can you work from our existing model or study?

Yes. We can review previous work, update data where needed, and bring the study in line with current standards and your present system configuration.